The beginning of Hangbird’s plumage is the choice of the right material: natural fibres are not tough enough, in particular if they are in touch with humidity. Also, they could stain and are available in few colours only.

However, polyester stands out by its durability, resistance against humidity and UV light, hence it is the material of choice: very tough in weather, light-resistant and tough mechanically.

The raw materials for the production of the ropes are kilometre-long fine fibres. Dozens of them are combined to form plies. The spools with the raw material are too big for the braiding machine, and hence the yarns are transferred to smaller spools before braiding – still kilometre-long.

Once threaded and fed with empty spools, the rewinding machine coils up the yarns onto smaller spools automatically.

The machine prepares empty spools and attaches the beginning of the yarn.

An eyelet moves across the spool forwards and backwards for a uniform distribution.

After a few kilometres, the small spool is full and is ejected – ready for braiding.

The machine prepares empty spools and attaches the beginning of the yarn.

An eyelet moves across the spool forwards and backwards for a uniform distribution.

After a few kilometres, the small spool is full and is ejected – ready for braiding.

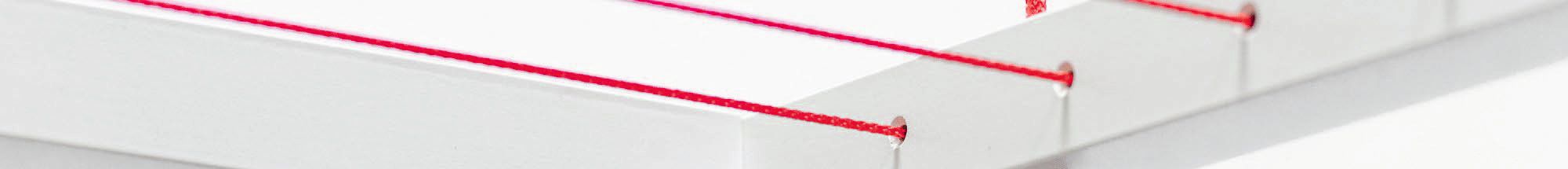

In a braiding machine, the spools move in two groups in opposite directions on meandering circles and they cross each other in pairs: the “up and down” of the braiding

The thinner clothes lines is braided directly; the ropes are braided around an inner core, that is braided itself: the “soul” of the rope.

The simplest pieces hold the biggest surprises:

The thin clothes lines is coiled up automatically: a machine takes the thread, winds it onto a cardboard core, cuts it, staples the end, ejects the finished spool, and the process starts over again.

The small piece for the pulley loop is cut by a complicated machine using heat in order that the ends are round and smooth. This detail allows to insert them easily into the metal end pieces.