Over 40 screws, clamps, hooks and other small parts are carefully counted using different auxiliary templates. Afterwards, all counted small parts are collected and are ready for packaging.

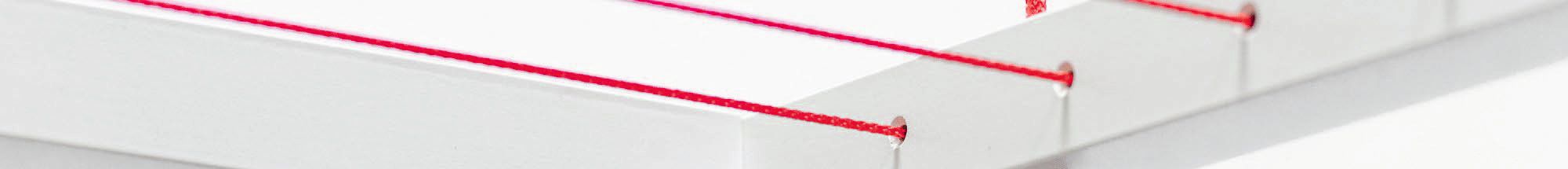

The smaller parts are first packaged in a pouch, ensuring that everything stays together when Hangbird is sent to its new owner. By the way, it is the only piece of plastic that Hangbird uses in its packaging.

The little pouch is now ready for further packaging together with the ropes, the cleat and the pulley wheels. It is important to pack these parts separately in a purpose made carton, otherwise they could damage the wooden frame during shipping – especially the heavy pieces made of metal.

Incidentally, this carton is not only a neat storage for the small parts and ropes, but it also fulfils another important function in the finished shipping packaging: As a “plug”, it fixes the laths internally in the carton and thus prevents them from dislocating during transport.

At the end of the day, it is important that a sticker on the box shows the seven different colours of the ropes – white, gray, pink, blue, orange, red and bordeaux. When the individual Hangbird is finally dispatched, the colour chosen by the customer can be then easily added to the package.